GEOPOLYMER MATERIALS & TECHNOLOGY

Gemite® Group has been developing and manufacturing advanced specialty materials for structural restoration, waterproofing and lining of water, wastewater and infrastructure since 1980’s. Gemite® Materials and Systems have been field tested and verified to extend life span of deteriorated structures to over 50 years.

Geopolymers deliver better physical performance than traditional Portland concrete and provide additional advantages, even in extreme environments, while significantly reducing greenhouse emissions.

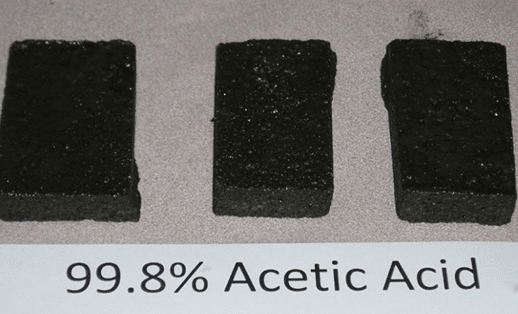

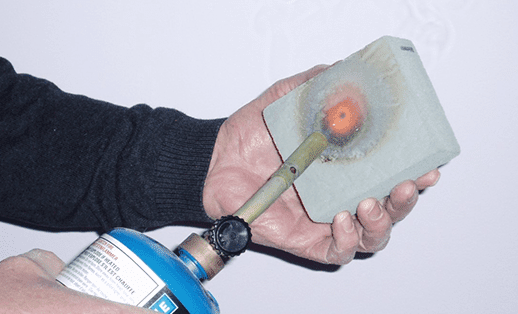

Geopolymers offer superior chemical resistance to corrosion, acid and alkali attack, deliver high resistance to temperature and fire, and are better suited in most exposure conditions in various industrial markets, including power production, chemical industry, and oil and gas.

TECHNOLOGICAL BREAKTHROUGH

Convert Waste materials into High-Profit Materials and Products

Gemite’s Technological Advantage allows to repurpose local fly ash or slag into geopolymer coatings, mortars or precast products. Using customized mix designs, most waste and inexpensive raw materials are transformed into high-performance products with significantly higher added value.

Geopolymer Technical Parameters can be Customized for Specific Application

An extensive database allows us to quickly formulate customised products that satisfy variety performance parameters required, using raw materials from virtually any source.

Blast furnace slag (iron production waste) and fly ash (coal-fired power generation waste) can be converted into high profit materials using chemical activation.

Materials are 2-component or 1-component

CORRO-CHEM PROPERTIES

SEWER REHABILITATION

Geopolymer spray lining is a high performance, high strength, ultra-low porosity mortar specifically designed to rapidly form a new structural lining inside the existing sewer pipe. Application can be done regardless of pipe shape, deformities, turns, slopes and separated joints, and Corro-Chem™ bonds tenaciously to virtually any surface.

NEW PRODUCTS UNDER DEVELOPMENT

Corrosion Protective Coating for Steel Structures

CUI (Corrosion Under Insulation) Protective Coating

Flexible Geopolymer

Materials