Geopolymer Materials

Corro-Chem™ are cost-effective, next-generation geopolymer formulations containing at least 70% raw materials that are reactive. Corro-Chem™ materials can be sprayed, trowelled, poured and cast – properties can be adjusted for needs of large-scale users.

Components of Corro-Chem™ provide barrier protection for reinforcing bars = eliminates use of active passivating coatings.

Added benefit of Corro-Chem™ is the significant reduction of carbon footprint, since production, use and chemical reaction create only a fraction of the CO2 emissions that conventional Portland cement materials produce.

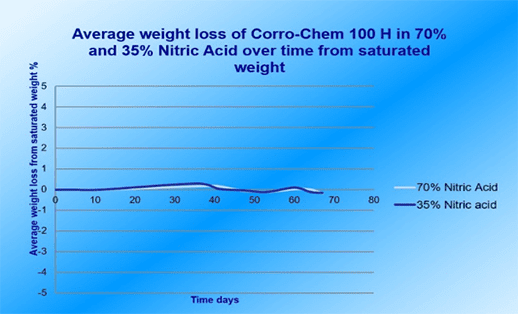

Geopolymers cure chemically, instead of hydration, and have similar workability and feel as cement, but with an extended Service Life. Geopolymer chemical structure is comparable to a natural stone = Corrosion Resistant and Durable.

2-Component materials

Corro-Chem™ 100 + Corro-Chem™ 200

- Resistant to temperatures up to 1,500o F (800o C)

- Completely Non-Flammable + Non-Toxic

- Bond to Chemically Contaminated surfaces

- Bond to Wet surfaces

- One-Coat Simple Application

- High Abrasion Resistance

- Vapor Permeable (breathable)

- Non-flammable & Nontoxic

- Resistant to high thermal shock

- Less Expensive than complicated Polymer systems