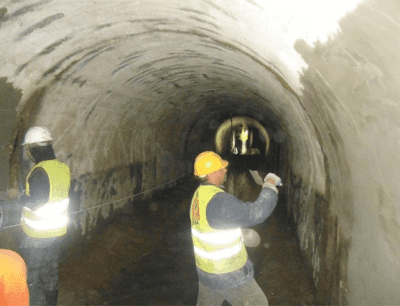

Sewer Rehabilitation

Geo-Mortar spray lining is a high performance, high strength, geopolymer mortar formulated as sprayable liner to restore deteriorated sewers and pipes. Geo-Mortar bonds tenaciously to virtually any surface and can be used regardless of x-section (round, oval, rectangular or egg shape).

Geo-Mortar is a Cost effective and Environmentally friendly solution to serious deterioration problems of aging storm and water pipes, regardless of the existing conditions.

Geo-Mortar can be spray or spin cast applied in one pass to form strong and protective layer on horizontal or vertical surfaces, and cures quickly, minimising bypass time and allows service to be re-established much quicker than cement mortars.

The application provides trenchless system for repair of aging pipe infrastructure and allows spray application in-situ to restore strength and flow. By not requiring digging, it practically eliminates traffic interruptions and eliminates greenhouse gas emissions caused by idling cars and trucks.

Geo-Mortar system delivers cost effective solution + cost savings to applicators & infrastructure owners.

Alternative solutions have significant environmental issues. CIP liners use polymer resin containing styrene, which may leach contaminates into the water systems.

Spray applied Geo-Mortar lining is solvent free and qualifies for LEED credits.

Geo-Mortar has better resistance to chemical agents and improved mechanical properties even in extreme conditions.

Key Benefits

- Increases Structural Integrity

- High Compressive & Flexural strength

- Corrosion resistant in a high hydrogen sulfide environment (as low as 1.0 pH)

- Resistant to acid in industrial effluent at temperature exceeding 285° F (140° C)

- Extremely Low Permeability

- Suitable for deep sewers & pipes and restricted access

- Solid bond to any concrete and steel

- Applied by Trowel, Spray or Spin-Casting

- Significant Cost Advantages

- Reduces Bypass Operation

- Easily tackles irregular shapes, bends and intrusions

- Eliminates Infiltration of Groundwater

- Geo-Mortar is Eco-friendly with very low CO2 emissions.

Sewer – Restoration & Waterproofing

Structural Strengthening

Corro-Mortar™ replaces polymeric (epoxy) systems that have been used in structural strengthening applications.

Corro-Mortar™ can be used with carbon and glass fabrics, and offers following advantages:

- Ideal for Structural Reinforcing applications

- Excellent fire resistance – retains 50% of its flexural strength after a fire

- Does NOT Ignite, Burn, or release Smoke – even after Exposure to extended heat

- Safe = Reduces fire hazard associated with polymeric (epoxy) coatings

- Bonds to Wet & Contaminated surfaces

- Bond to concrete is better & more reliable than organic polymer materials

- Safer and User-Friendly Application

- Significantly Lower Cost than polymeric (epoxy) systems

Bridge – Carbon Fabric Reinforcement

Other Markets for Corro-Chem™, Geo-Mortar™ or Geo-Cast™

- Chemical Plants utilizing Inorganic Acids (sulfuric, hydrochloric, nitric and phosphoric acids)Chlor-Alkali, Phosphate Fertilizer, TiO2 & EDC/VCM (Ethylene Dichloride / Vinyl Chloride Monomer)

- Surface Protection & Secondary Containment

- Acid Proof Construction

- Mining – Hydrometallurgical Processing

- Petrochemical processing

- Flue Gas Desulfurization & Carbon Capture

- Pulp and Paper

- Acid Resistant Brick & Tile

- Polymer Concrete Replacement

- Thermal Insulation materials

- Manholes, Culverts & Tunnels

- Tanks for Chemical Liquids

- Fireproof systems

- Radioactive substances Containment & Encapsulation systems

Pit Sarnia – after application of Corro-Chem™ 100